Siniat Cornice

Description

Plaster cornice or cove is decorative profile made from a core of gypsum faced with heavy duty recycled paper. Paper-faced cornice enables clean-cut designs and is lightweight. It protects the plaster core and allows for easy painting. At the same time the paper facing increases the durability of the plaster cornice profile during transportation, handling and installation. It is designed to decorate and conceal the junction of walls and ceiling. It is lightweight for fast and easy installation. Available in a variety of profiles and lengths to suit application and style. Choose from:

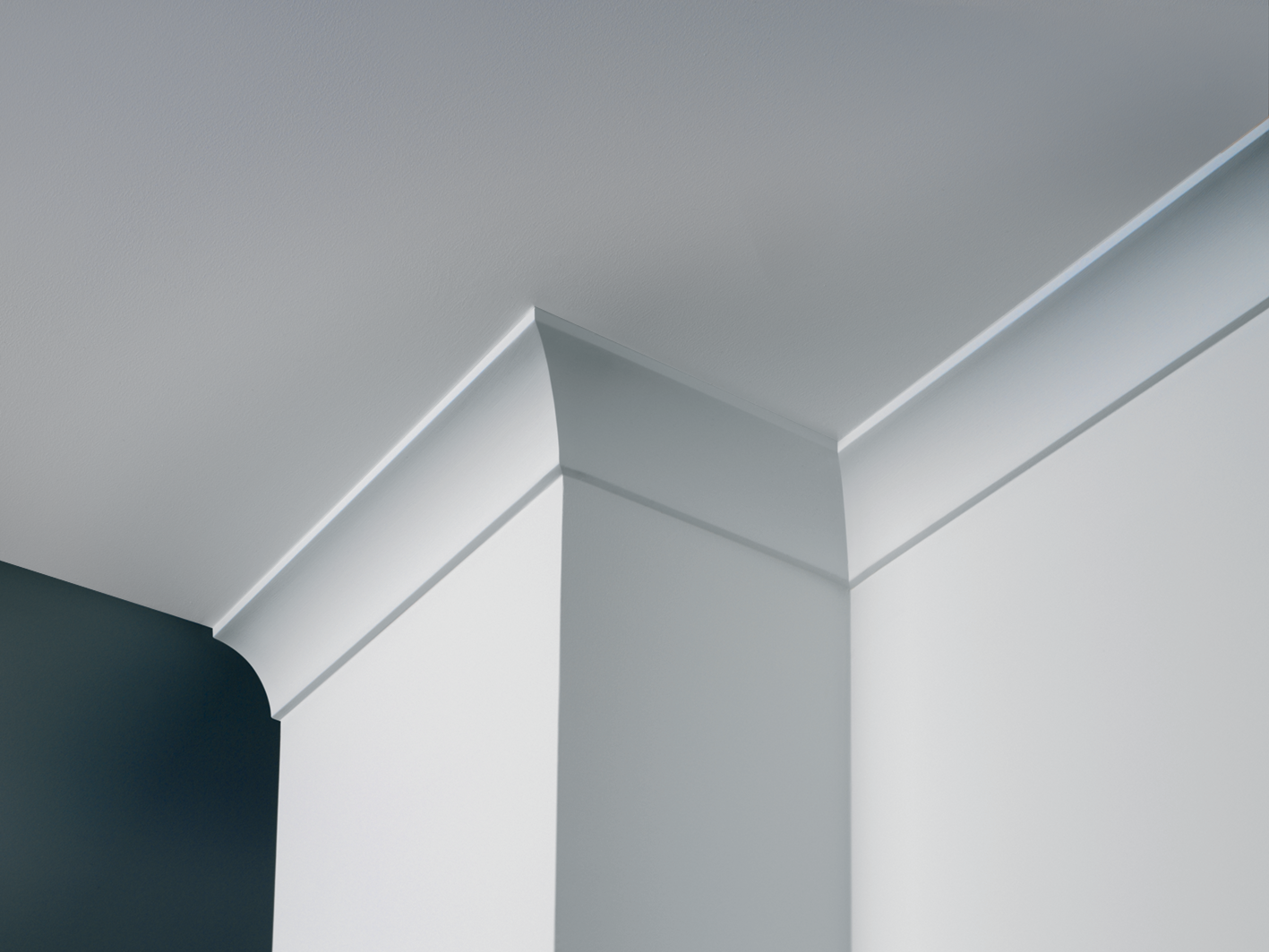

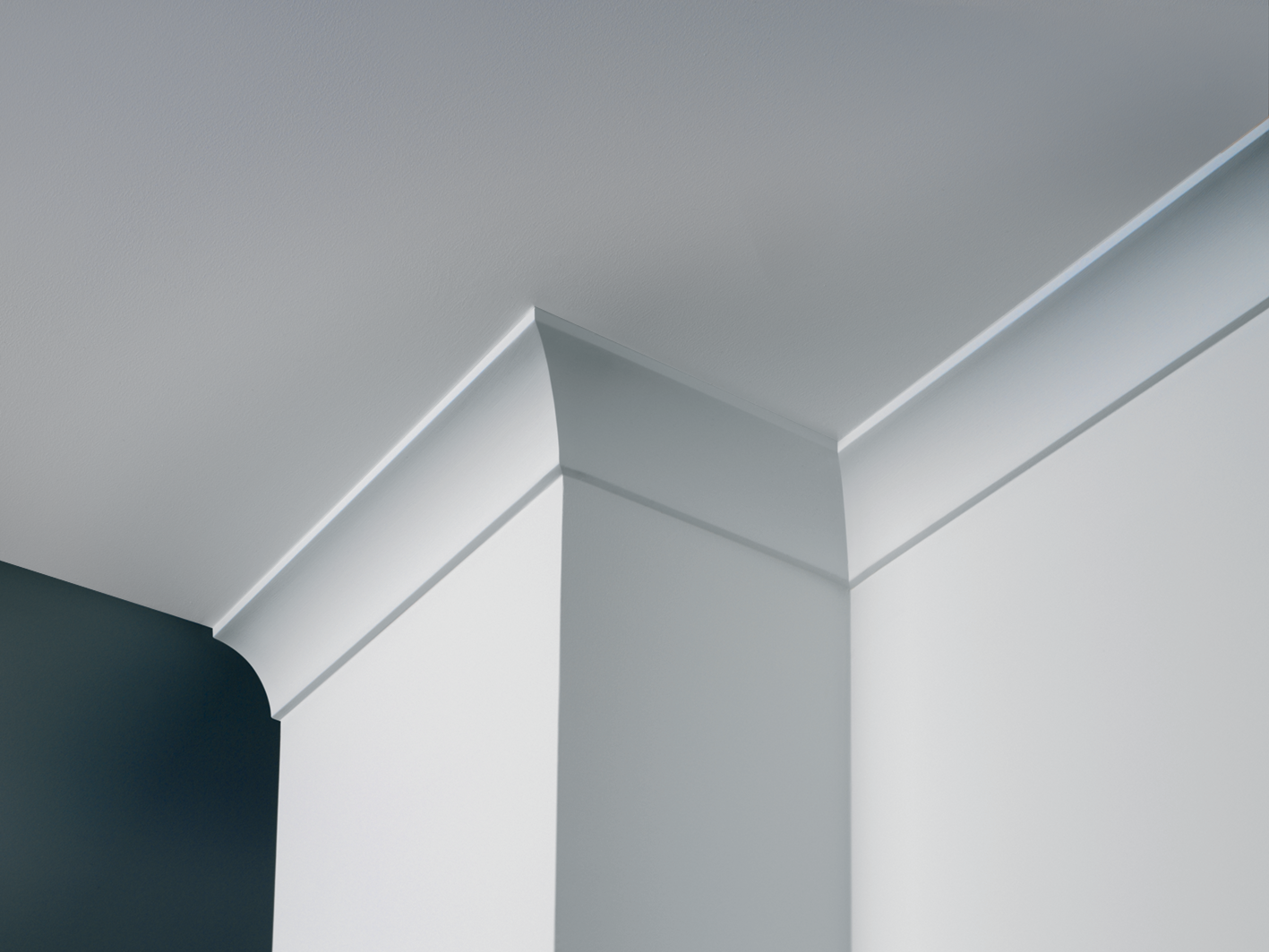

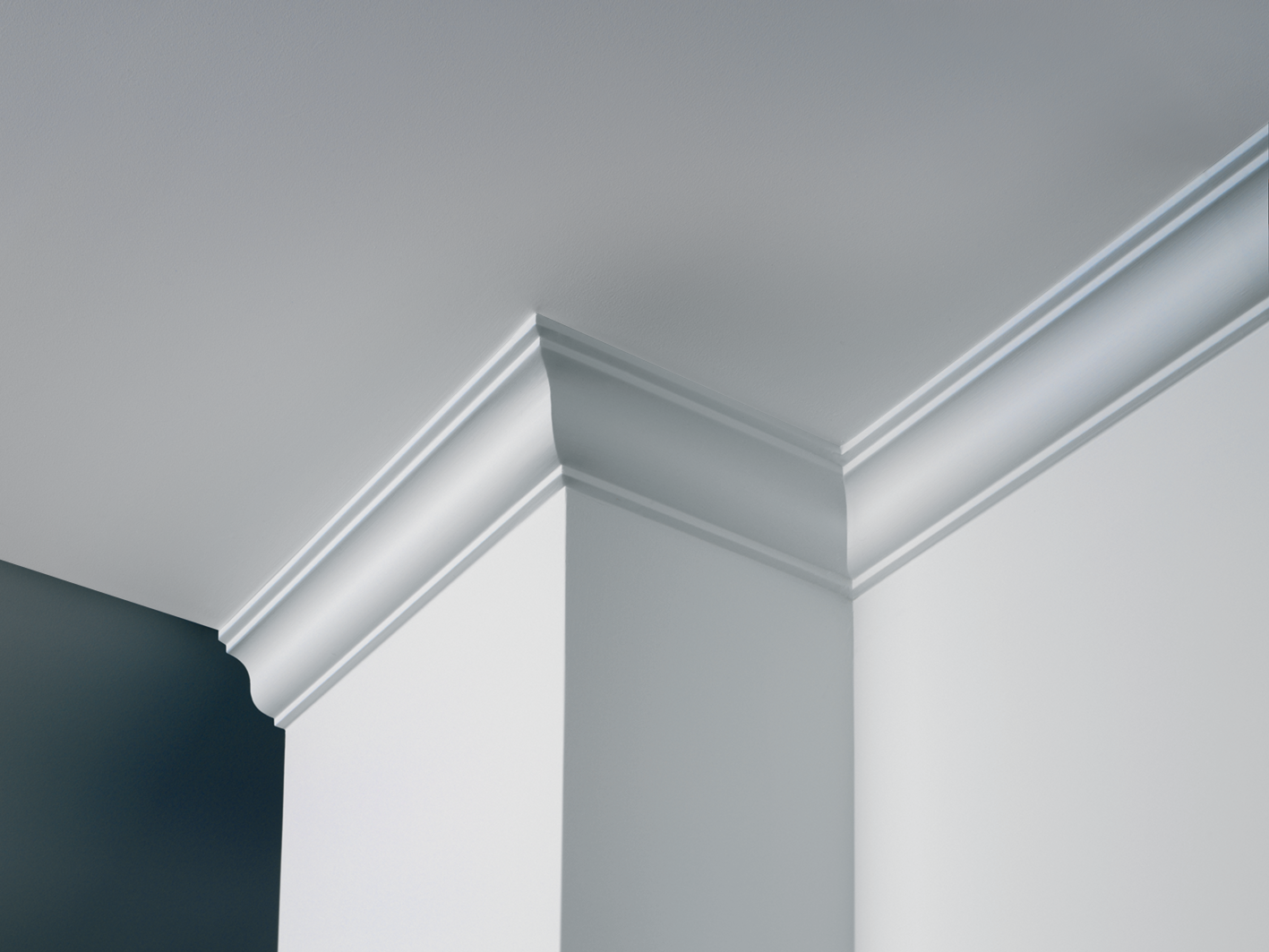

- classiclook A simple, curved profile that delivers a clean finish to suit all decors.

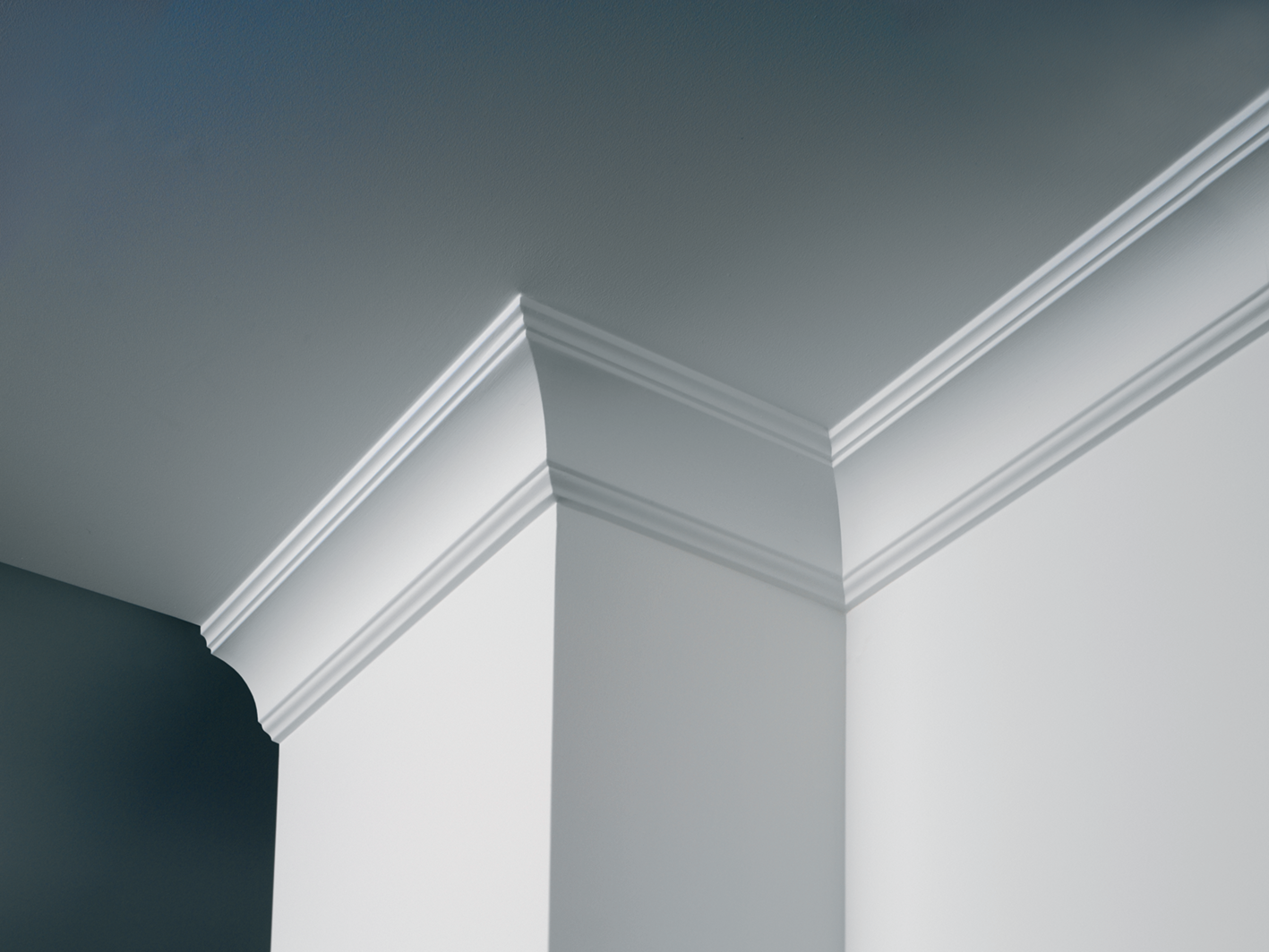

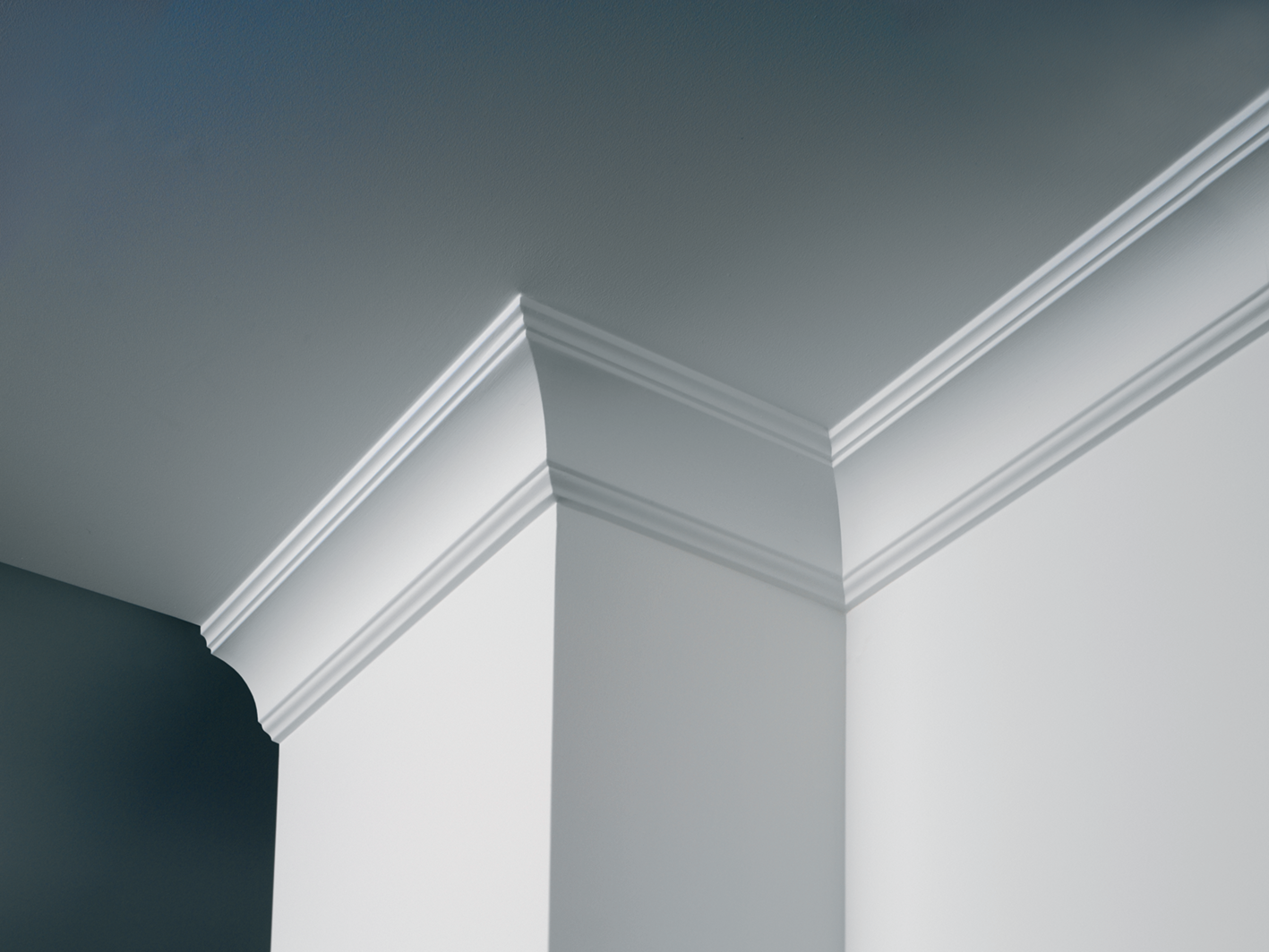

- wavelook An elegant, soft curved profile that adds a smooth, relaxing style.

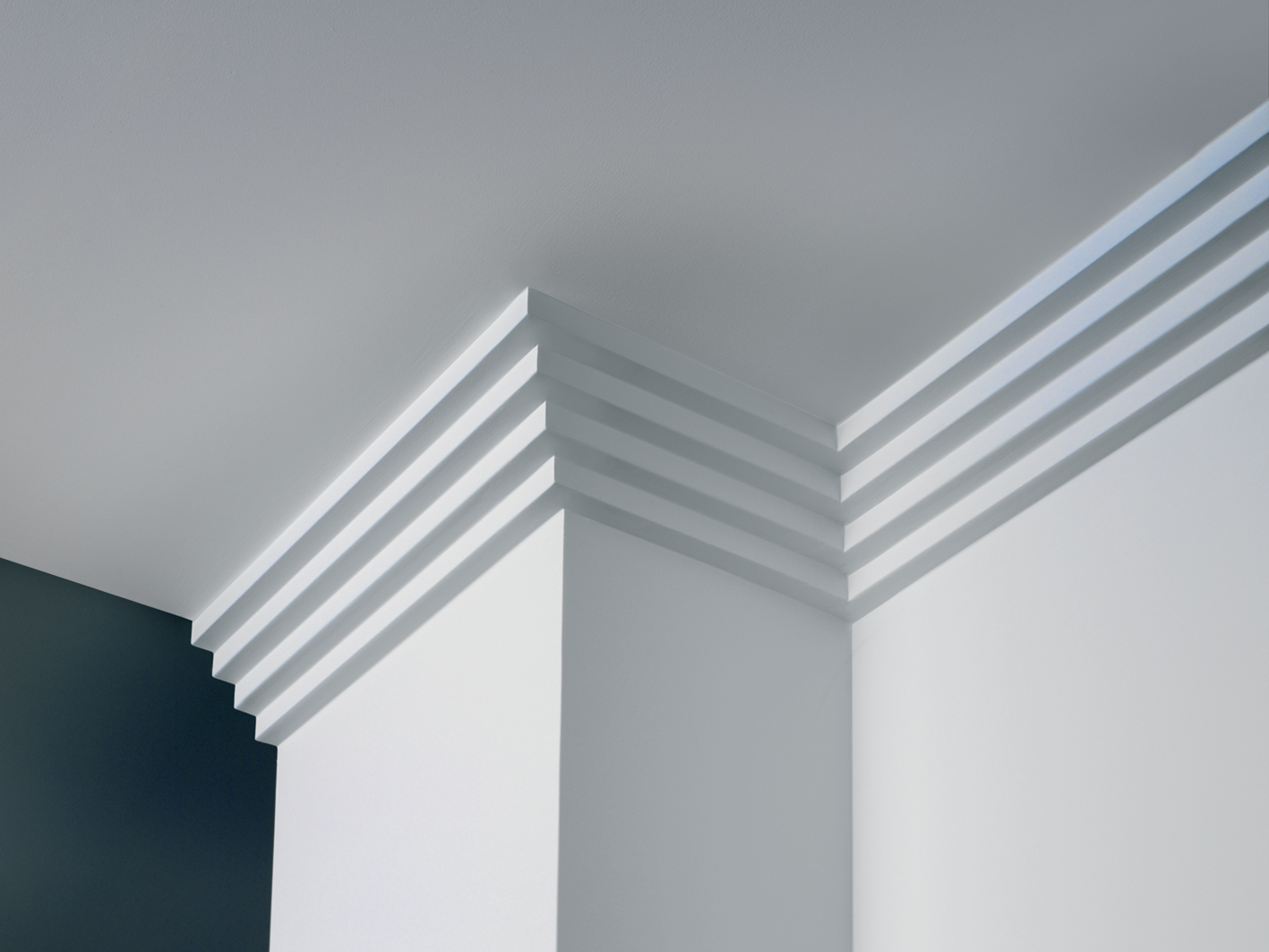

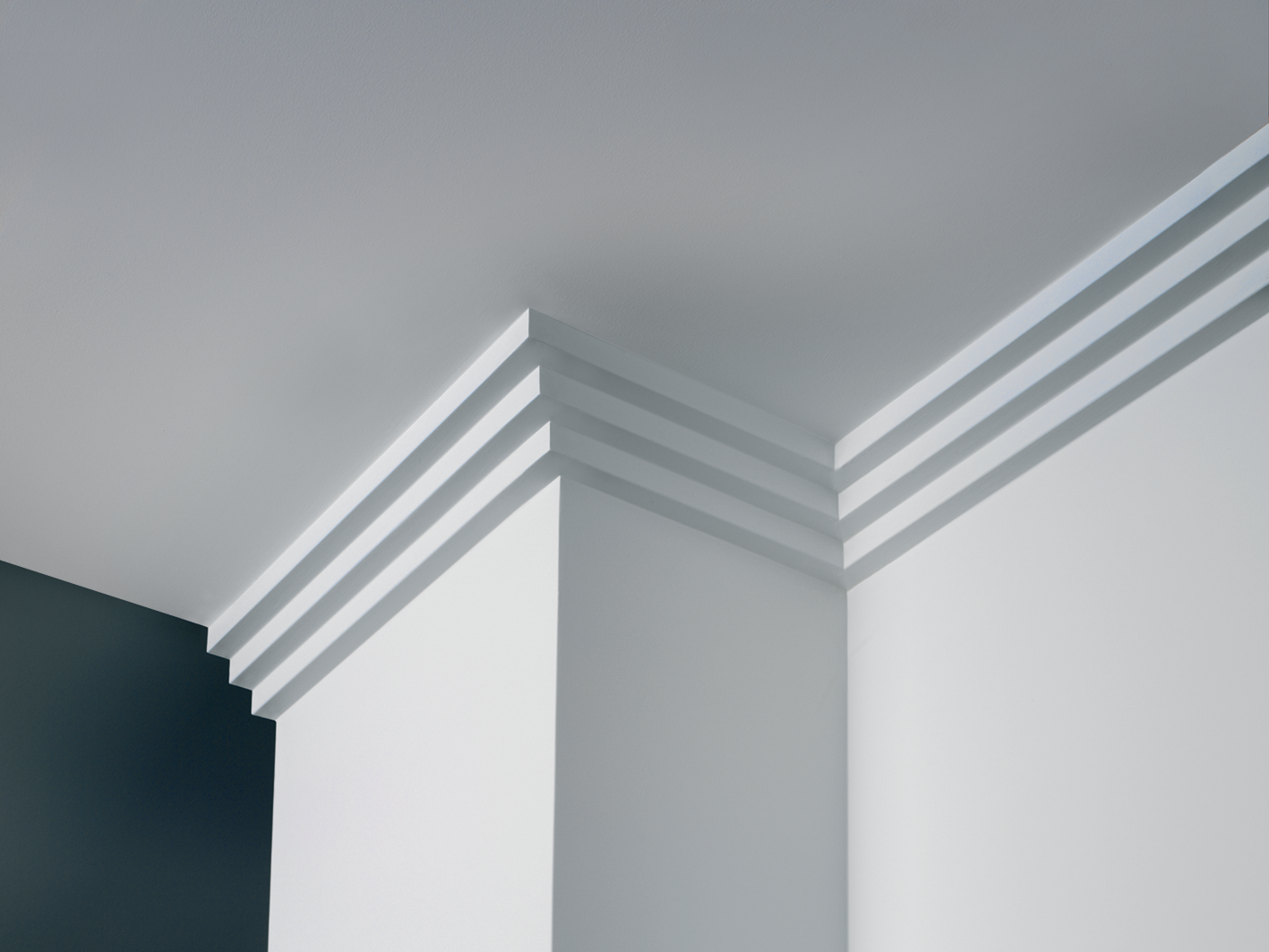

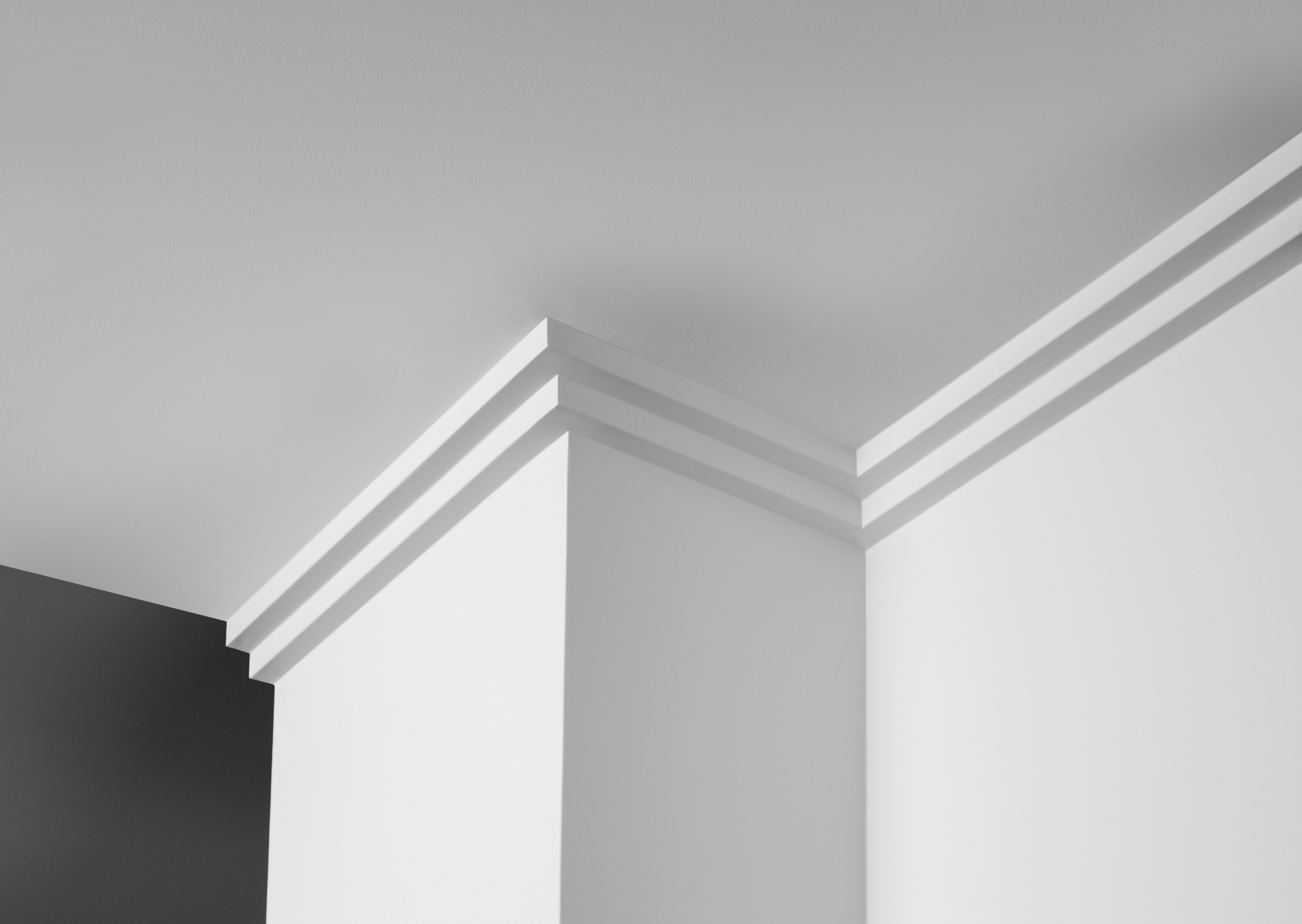

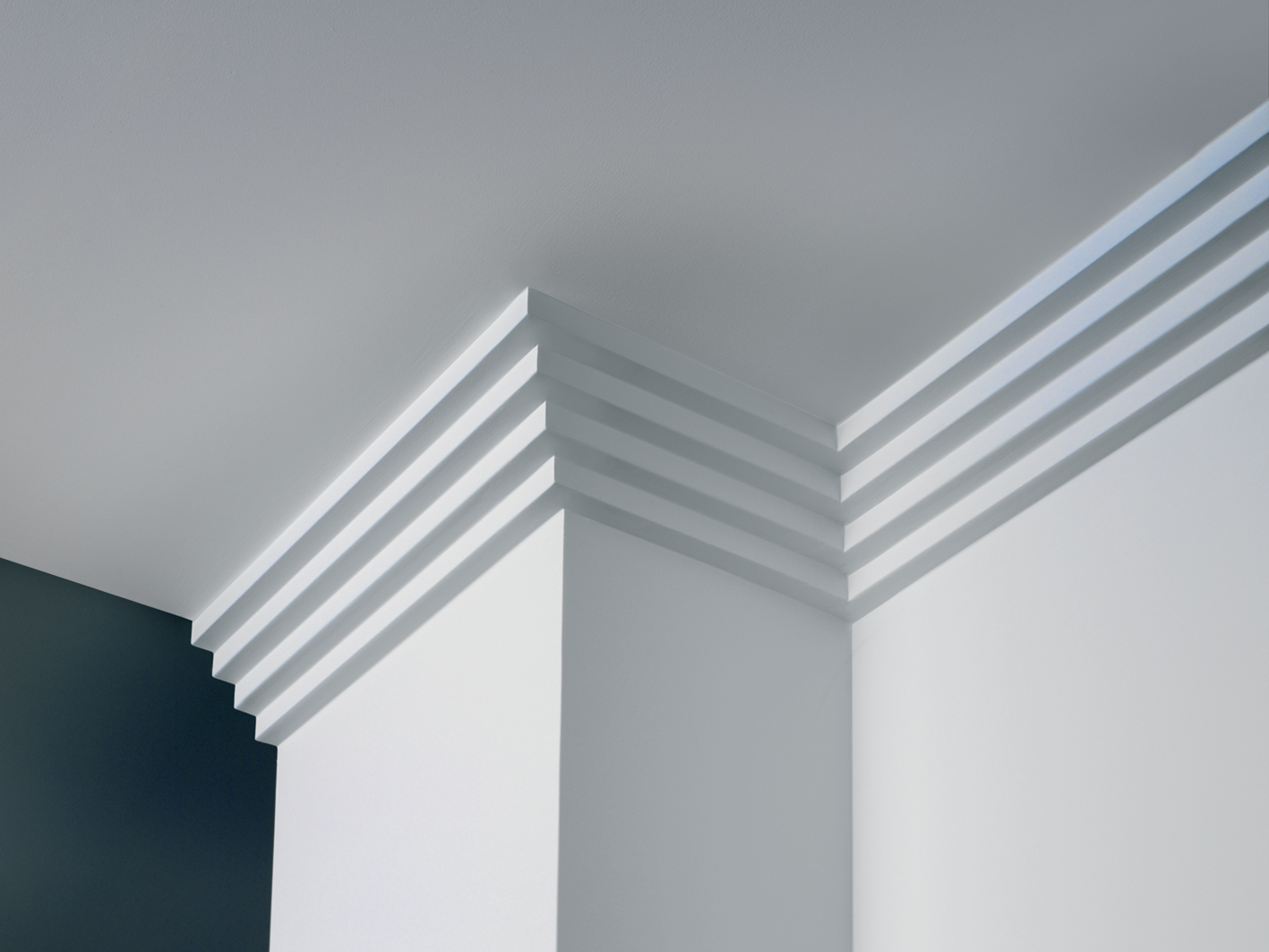

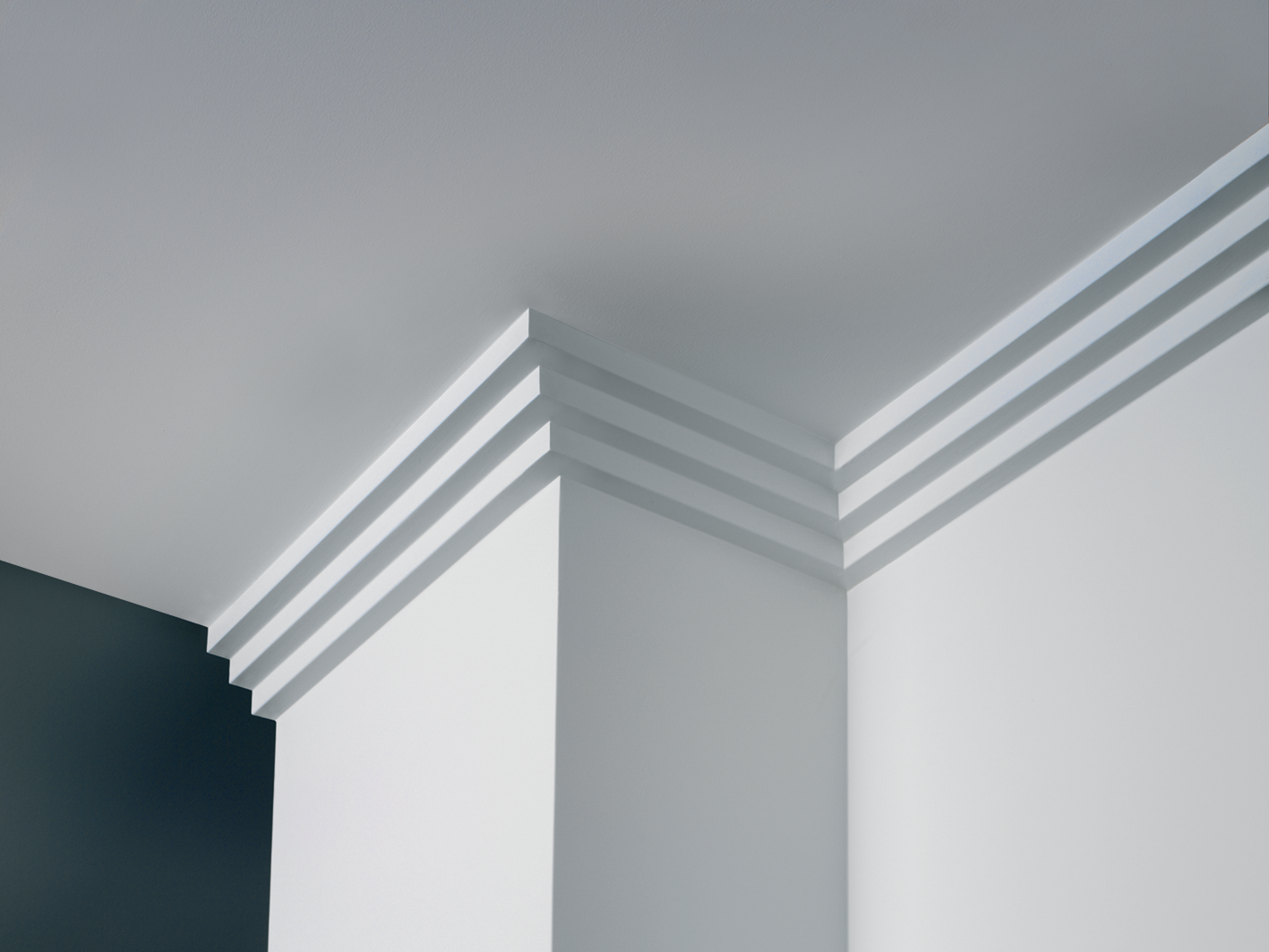

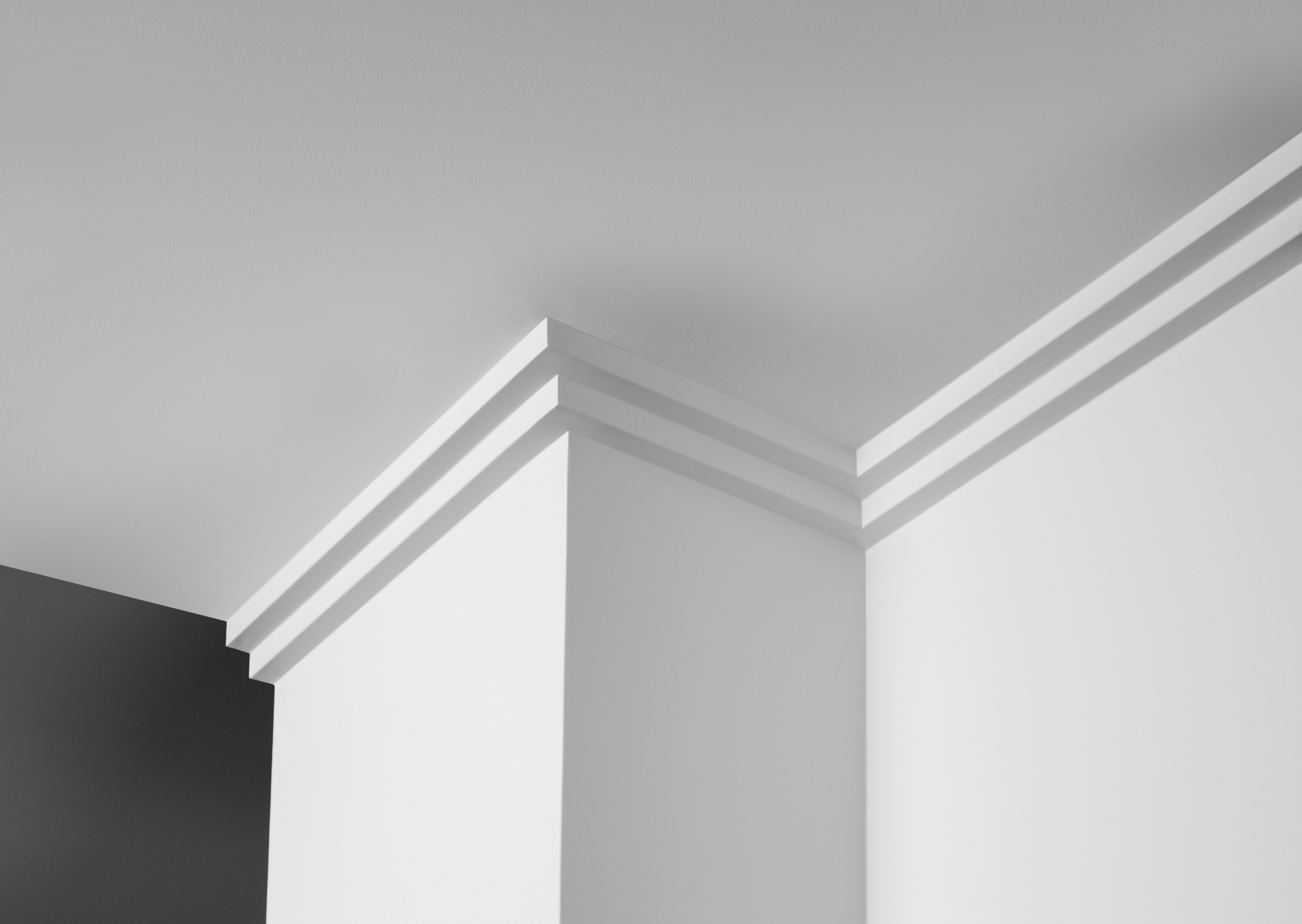

- steplook Contemporary 2, 3 and 4 step profile that adds depth, edge and dimension.

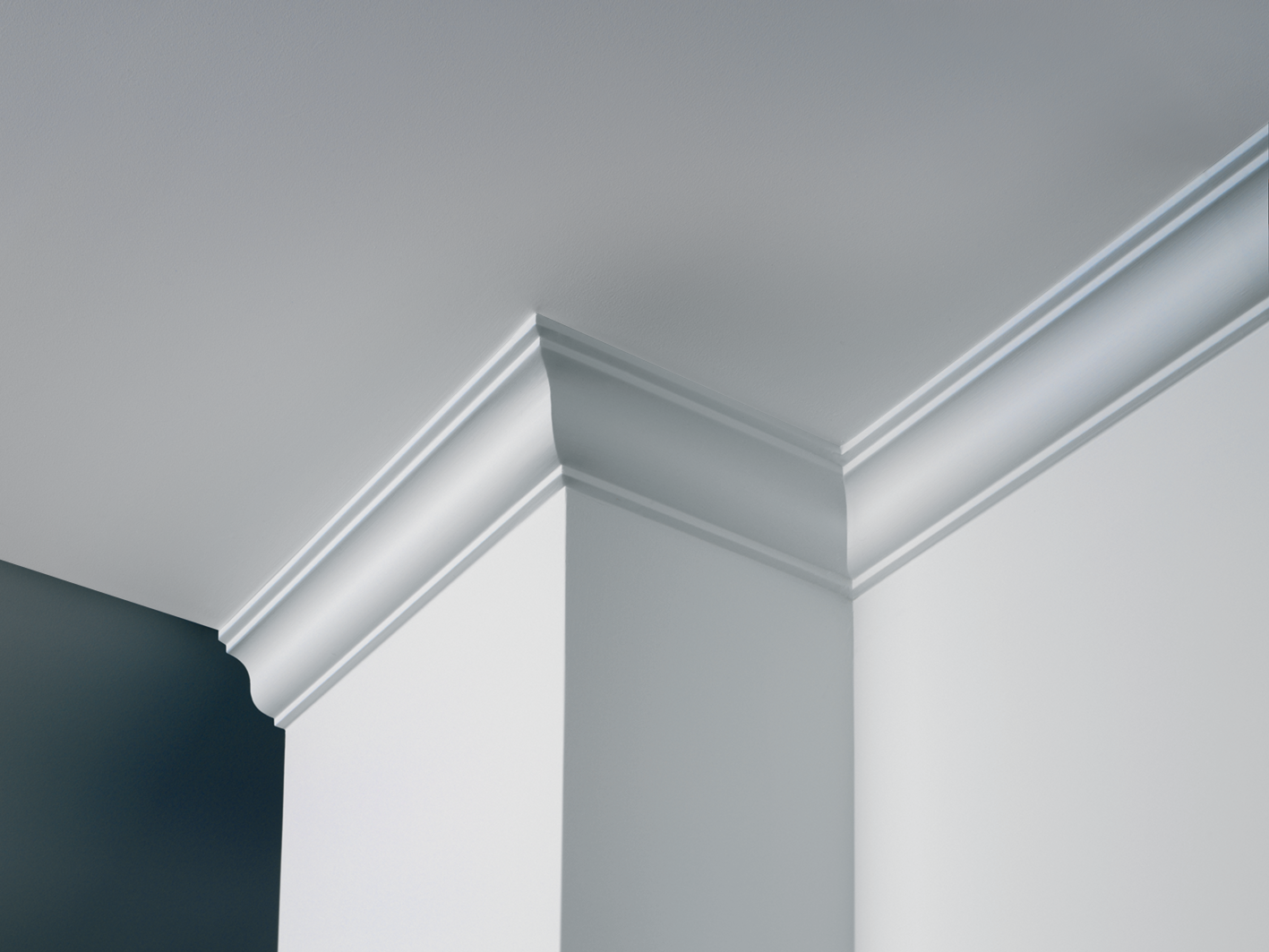

- pacificlook Delivers bold curves, combined with a smooth profile. Can be retrofitted over existing 55mm cornice.

- skylook Sharp lines combine with a smooth profile. Can be retrofitted over existing 55mm cornice.

- Economical light weight construction

- Easy to install

- Available in a range of lengths and profiles to suit every requirement in regards to application and style

| SPECIFICATIONS | Plasterboard Description | Width (mm) | Length (mm) | Weight (kg/m2) |

|---|---|---|---|---|

| QLD Specs | classiclook cornice | 55 | 3600 | 0.65 |

| QLD Specs | classiclook cornice | 55 | 4800 | 0.65 |

| QLD Specs | classiclook cornice | 55 | 5400 | 0.65 |

| QLD Specs | classiclook cornice | 75 | 4800 | 1.05 |

| QLD Specs | classiclook cornice | 75 | 5400 | 1.05 |

| QLD Specs | classiclook cornice | 90 | 3600 | 1.3 |

| QLD Specs | classiclook cornice | 90 | 4800 | 1.3 |

| QLD Specs | classiclook cornice | 90 | 5400 | 1.3 |

| QLD Specs | wavelook cornice | 75 | 4200 | 1.98 |

| QLD Specs | steplook 2 cornice | 50 | 4200 | 1.57 |

| QLD Specs | steplook 3 cornice | 75 | 4200 | 2.17 |

| QLD Specs | steplook 4 cornice | 100 | 4200 | 2.78 |

| QLD Specs | pacificLook cornice | 90 | 4200 | 2.1 |

| QLD Specs | skylook cornice | 90 | 4200 | 1.96 |

| NSW Specs | classiclook cornice | 55 | 3600 | 0.65 |

| NSW Specs | classiclook cornice | 55 | 4800 | 0.65 |

| NSW Specs | classiclook cornice | 75 | 4800 | 1.05 |

| NSW Specs | classiclook cornice | 90 | 3000 | 1.3 |

| NSW Specs | classiclook cornice | 90 | 3600 | 1.3 |

| NSW Specs | classiclook cornice | 90 | 4200 | 1.3 |

| NSW Specs | classiclook cornice | 90 | 4800 | 1.3 |

| NSW Specs | classiclook cornice | 90 | 5400 | 1.3 |

| NSW Specs | wavekook cornice | 75 | 4200 | 1.98 |

| NSW Specs | steplook 2 cornice | 50 | 4200 | 1.57 |

| NSW Specs | steplook 3 cornice | 75 | 4200 | 2.17 |

| NSW Specs | steplook 4 cornice | 100 | 4200 | 2.78 |

| NSW Specs | pacificlook cornice | 90 | 4200 | 2.1 |

| NSW Specs | skylook cornice | 90 | 4200 | 1.96 |

| VIC Specs | classiclook cornice | 55 | 3600 | 0.65 |

| VIC Specs | classiclook cornice | 55 | 4800 | 0.65 |

| VIC Specs | classiclook cornice | 75 | 4800 | 1.05 |

| VIC Specs | classiclook cornice | 90 | 3600 | 1.3 |

| VIC Specs | classiclook cornice | 90 | 4800 | 1.3 |

| VIC Specs | wavelook cornice | 75 | 4200 | 1.98 |

| VIC Specs | steplook 2 cornice | 50 | 4200 | 1.57 |

| VIC Specs | stepLook 3 cornice | 75 | 4200 | 2.17 |

| VIC Specs | stepLook 4 cornice | 100 | 4200 | 2.78 |

| VIC Specs | pacificlook cornice | 90 | 4200 | 2.1 |

| VIC Specs | skylook cornice | 90 | 4200 | 1.96 |

| SA Specs | classiclook cornice | 55 | 3600 | 0.65 |

| SA Specs | classiclook cornice | 55 | 4800 | 0.65 |

| SA Specs | classiclook cornice | 75 | 3600 | 1.05 |

| SA Specs | classiclook cornice | 75 | 4800 | 1.05 |

| SA Specs | classiclook cornice | 90 | 3600 | 1.3 |

| SA Specs | classiclook cornice | 90 | 4800 | 1.3 |

| SA Specs | steplook 3 cornice | 75 | 4200 | 2.17 |

| TAS Specs | classiclook cornice | 55 | 3600 | 0.65 |

| TAS Specs | classiclook cornice | 55 | 4800 | 0.65 |

| TAS Specs | classiclook cornice | 75 | 4800 | 1.05 |

| TAS Specs | classiclook cornice | 90 | 3600 | 1.3 |

| TAS Specs | classiclook cornice | 90 | 4800 | 1.3 |

| TAS Specs | wavelook cornice | 75 | 4200 | 1.98 |

| TAS Specs | steplook 2 cornice | 50 | 4200 | 1.57 |

| TAS Specs | stepLook 3 cornice | 75 | 4200 | 2.17 |

| TAS Specs | stepLook 4 cornice | 100 | 4200 | 2.78 |

| TAS Specs | pacificlook cornice | 90 | 4200 | 2.1 |

| TAS Specs | skylook cornice | 90 | 4200 | 1.96 |

| WA Spces | classiclook cornice | 55 | 3600 | 0.65 |

| WA Spces | classiclook cornice | 55 | 4800 | 0.65 |

| WA Spces | classiclook cornice | 75 | 3600 | 1.05 |

| WA Spces | classiclook cornice | 75 | 4800 | 1.05 |

| WA Spces | classiclook cornice | 90 | 3600 | 1.3 |

| WA Spces | classiclook cornice | 90 | 4800 | 1.3 |

| WA Spces | steplook 3 cornice | 75 | 4200 | 2.17 |

*Non-stock item for this location – lead times and minimum order quantities apply.

Weights indicated are nominal.Special sizes and other edge types available, minimum order quantity and lead times apply – please contact us with your requirements.

What is back-blocking?

Back-blocking is the process of reinforcing wall and ceiling joints with cut-to-size pieces of plasterboard adhered across the back of the joint with MastaBlock Back-Blocking Cement or Cornice Cement such as MastaCove45. Back-blocking helps prevent joint cracking and peaking caused by building movement, especially in large ceiling areas. Back-blocking forms part of the plasterboard lining standard AS/NZS 2589:2007, and manufacturers’ guarantees/warranties may be void if back-blocking has not been carried out. All back-blocking must be completed before commencing jointing. Each ‘Level of Finish’ has specific back-blocking requirements. For more information refer technical-manual-download Siniat’s technical literature.

What substrates can plasterboard be fixed to?

Plasterboard can be fixed to various substrates that form wall partitions, ceilings, bulkheads or ducting. Plasterboard is most commonly fixed to steel studs, timber studs or masonry for wall partitions. Plasterboard can be fixed to ceiling framing by either directly fixing to the joists or by first installing a metal furring channel and then fixing the plasterboard to the furring channel. Furring channel is also used to fix plasterboard linings for suspended ceilings or as an alternate method for fixing plasterboard to masonry on walls. All methods of the installation can be found in Siniat’s technical literature.

What methods of fixing should I use to install plasterboard?

The Australian Standard AS/NZS 2589:2007 allows three ways to fix plasterboard to steel or timber substrates. The options are screw fix only, nail fix only or a combination of either screw or nail with adhesive. The preferred method is to use screws or nails with adhesive. The nail fix only method is only suitable for a Level 3 Finish. Please refer to Siniat’s technical literature or AS/NZS 2589:2007 for correct installation details such as the spacing of fasteners and adhesive for each method and correct screw/nail type and size.

What are the maximum steel/timber framing centres for plasterboard?

| Plasterboard Type and Thickness | Walls (mm) | Ceilings (mm) | For ceiling areas of intermittent high humidity e.g bathrooms and external ceilings |

| MastaShield10mm | 600 | 450 | 300 |

| MastaShield13mm | 600 | 600 | 450 |

| SpanShield10mm | 600 | 600 | 450 |

| Opal10mm | 600 | 600 | 450 |

| SoundShield10mm and 13mm | 600 | 600 | 450 |

| WaterShield 10mm and 13mm | 600 | 600 | 450 |

| FireShield 13mm and 16mm | 600 | 600 | 450 |

| TruRock 13mm and 16mm | 600 | 600 | 450 |

| TruRock HD 13mm | 600 | 600 | 450 |

| Designpanel | 600 | 600 | – |

| CurveShield 6.5mm | 550 | 550 | – |

*For CurveShield refer to Siniat’s Technical Manual for more information on the maximum frame spacing and minimum curve radius. Note: For plasterboard fixed to masonry refer to Siniat’s Technical Manual.

What is the best way to paint plasterboard once it is installed?

When installed in accordance with Siniat installation guidelines, the finished surface of all Siniat plasterboard accepts most types of decorative finish: emulsion or oil based paints, stipples, enamels, textured coatings and wallpapers. Matt finishes give the best appearance; gloss or sheen finishes tend to highlight any surface irregularities, as will harsh or glancing light. In order to obtain the best finish to the walls, Siniat recommends the following: Lay down the nap of any scuffed areas using MastaFinish, MastaLite or MastaGlide jointing compounds. The surface should be free of dust and other foreign matter. Ensure that the joint treatment is thoroughly dry before applying the sealer. Always seal over jointed and unjointed areas. Use roller application for paint. Overworking of sealant coat on jointed areas may cause paint to lift. Roller application applies uniform texture over the entire surface. Use only the best quality paints and other finishes. Use of sealers or undercoats that are water-based is preferred to reduce the possibility of raising the paper linerboard nap. Lightly sand between coats if nap is raised. Apply finishes in strict accordance with manufacturers’ instructions.

How do I finish a plasterboard joint once the sheet has been fixed?

There are only two types of joints formed when installing plasterboard – recessed edge joints or butt joints. The recessed edge joint is formed along the length of the sheets and the butt joint is formed along the width of the sheet. The finishing method is the same for both types of joints, but the width of compound coverage varies. Siniat recommends the use of paper tape with a three-coat compound application: two base coats (or bedding coats) and a third finishing coat.

How far apart should I install Control Joints?

Control joints must be installed to relieve stresses imposed by structural movement including those due to excessive changes in temperature and humidity. In long, unbroken partitions of wall or extensive ceiling areas, control joints should be placed not more than 12 metres in either direction, at any change in the substrate material and should be aligned with control joints in the structure. Control joints should also be considered at intersecting doorways, large light fixtures, heating vents and air diffusers.

What type of plasterboard do I need to use for a Fire Rating?

Only FireShield, MultiShield, TruRock, TruRock HD, ShaftLiner and GIB X-Block can be used in fire-rated systems. Please refer to the Siniat Technical Manual for wall, ceiling, column and beam encasement and ducting systems.

What is glancing light?

Glancing light refers to light being cast along the face of a surface showing minute undulations. As a result of this light being cast, a shadow is produced on the other side of the undulation. This draws attention to surface texture variations such as plasterboard joints and patches, which under more diffused light would not be visible. The best way to overcome the effects of glancing light is to consider the following factors which will help to achieve the appearance of flatness:

- Design

- Natural and artificial lighting

- Paint effects and paint sheen

- Texture and porosity

- Level of Finish’

For more information of the cause, effect and remedial measures refer to Siniat’s technical newsletter ‘OnBoard Glancing Light’ and also the industry publication FWCIANZ Glancing Light.

BIM FILES

Siniat has a large library of CAD details for all types of systems.